Currently, architecture is experiencing a moment of profound transformation in terms of the requirements of habitability, interior well-being and energy efficiency and of the entire construction process. Among the many systems that have been emerging to drive these changes we find the Ytong cellular concrete blocks.

But it is not just a few blocks, Ytong has a whole series of elements and its own construction system that will allow us to build houses with high energy efficiency and high interior comfort without having to resort to the large number of different materials and techniques necessary. in a house built with a more traditional system. Although it is an almost century-old product (Ytong cellular concrete was created for the first time in 1924), little by little it has gained relevance in the construction sector. Ytong cellular concrete is composed of a mixture of sand, lime, water and a small amount of metal powder, cured in an autoclave and cut into blocks of great precision.

The system is mainly made up of 62.5 x 25 cm blocks with different thicknesses ranging from 5 to 36.5 cm. The other essential component of the system is an adhesive mortar that is applied in very small quantities and that holds the blocks together. Finally, it has special pieces for floors, roofs, lintels and bands. The advantage is that it allows us to build with a very small variety of elements and materials, which simplifies and speeds up both the orders and the work itself.

The construction process is relatively simple, in fact, anyone could do it with a little skill and with the help of an architect. The blocks are very light and easy to handle as they have handles, are tongue-and-groove to facilitate their placement and can be easily cut, even with a hand saw, to adjust them to the necessary measurements. The irregularities that may arise as the blocks are stacked and forming the walls are sanded manually. The result is very smooth walls, partitions and slabs in which all that remains is to incorporate the finishes.

In fact, the tools needed to build with this system come down to:

- Ytong notched trowels.

- Sanding board.

- rubber mallet

- Carbon saw or electric saw.

- Jigsaw and grooving saw.

To start building we will need a fresh, waterproofed and well-leveled mortar base to support the first row of blocks. As we have said before, the blocks are very light, only 20% of them are solid, the rest are tiny closed pores that give it magnificent thermal, insulating and acoustic properties.

Another interesting aspect of the system is that, being a good thermal insulator in itself, it does not require more layers (in Spain at least, we could save on thermal insulation), the building’s façade will be made up of a single sheet made up of these blocks , the finishes are applied directly on the Ytong walls.

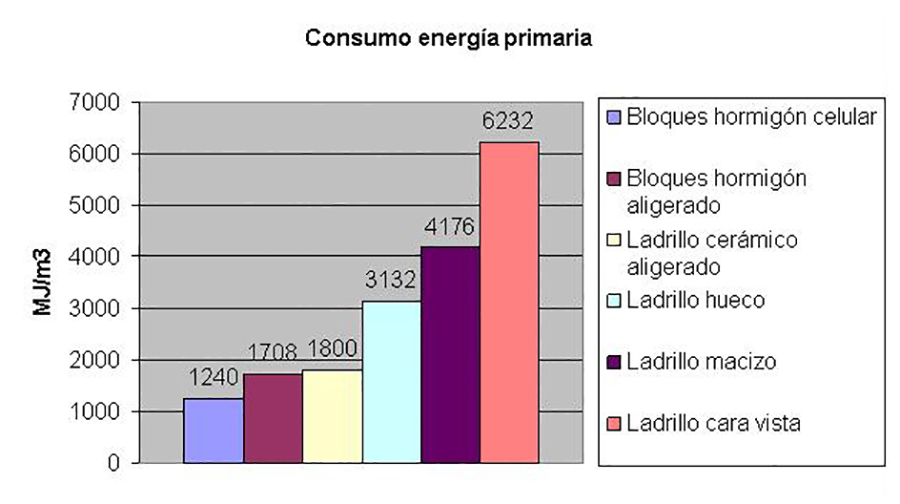

As for its manufacture, it is done in an autoclave and requires less energy than any other comparable traditional material. It requires 1m³ of raw material to generate 5m³ of final product. The dust and debris that are released throughout the process and when making the cuts are not polluting and in fact are reusable and are incorporated back into the production chain as raw material. It is therefore a material that respects the environment and is fully recyclable.

The installations are embedded in grooves that are made in the walls with the help of the grooving saw for the smallest ones and the electric saw for the most voluminous ones. It also has structural parts for slabs and roofs that incorporate a reinforcement, being able to reach spans of up to 6.60 m and overhangs of 1.5 m.

To top it off, Ytong cellular concrete blocks are non-combustible and very insensitive to thermal shocks so that in the presence of fire they do not crack, explode or release any type of harmful gas. In fact they are a very good option to build firewalls.

In summary, the Ytong system constitutes an effective and complete alternative to traditional systems, also achieving better results in terms of insulation and energy efficiency and even reducing costs and construction time. Even the complexity of its construction solutions is less than in other systems. Without a doubt, it is an option to take into account if we are looking for a home that is more respectful of the environment and efficient in every way.